Fire-resistant and flame-retardant wire and cable

- Tel:0550-7591188

- Fax:0550-7591188

- Email:2136705934@qq.com

Description

I. Product features and uses

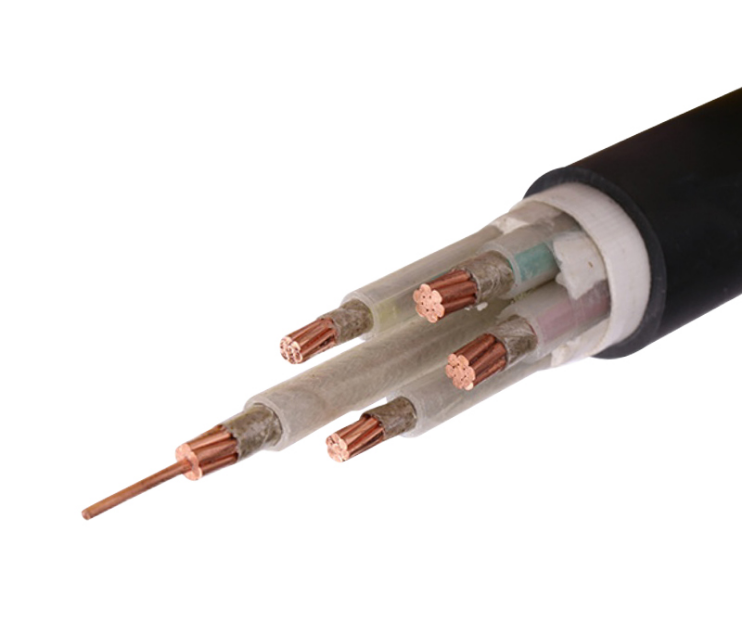

The flexible fire-retardant cable used in copper core emergency system developed and put into production by our company can keep the integrity of the circuit and ensure the safe and normal operation of the key emergency system in case of fire. At present, it is widely used in fire alarm system, smoke detection system, emergency lighting power system and public broadcasting system in large shopping malls, hospitals, offices, stations, airports, residential buildings and other buildings abroad.

The new type of fire-retardant cable has the following obvious characteristics:

1, the traditional fire retardant cable comparison, less acid gas smoke, its fire retardant performance is greatly improved, especially in the combustion, accompanied by water spray and mechanical shock under the condition of vibration, cable can still maintain the integrity of the line (that is, the line can work normally).

2. Compared with inorganic mineral insulated cable, it also has the following significant advantages:

A, because the new fire-retardant cable adopts twisted-pair or twisted-pair structure, it can obviously improve the clarity and transmission speed of data transmission.

B. Because of the shielding structure, the anti-interference performance is greatly improved, especially in the frequency range of 1-100mhz, attenuation can be reduced by 30-35dB.

C. Due to the significantly reduced core-to-core and core-to-shield capacitance of the newly developed cable, a larger length of cable can be used in the fire circuit, that is, its installation length is not limited. Here, the low capacitance of the cable is a very valuable performance parameter when installing the line.

D, the cable is flexible, the manufacturing length is not limited, reduce the joints in the line, do not need a lot of sealing accessories and expensive tools, improve the installation speed and reliability of the line.

Ii. Main performance indicators

1. Rated voltage: 300/500V;

2. Working temperature: -40℃--+90℃ (can not be bent when the temperature is lower than 0℃);

3. Minimum bending radius: 6 times the cable diameter. .com

4. Circuit integrity fire resistance test: BS6387 class C, W, Z; Code C: apply 300 volts horizontal combustion at 950℃ for 3 hours without breakdown. Code W: 650℃ to apply 300 volts of voltage burning for 15 minutes and then drench the water burning for 15 minutes without breakdown. Code Z: apply 300 volts at 950℃ while burning at the same time every 30 seconds mechanical shock vibration for 15 minutes without breakdown.

Comparison of fire resistance test conditions for circuit integrity

| British BS6387 standard | International IEC-331 standard | category model | |||

| Horizontal combustion test | Temperature ℃ | Time h | Temperature ℃ | Time h | |

| 650 | 3 | There is no | There is no | - | |

| 750 | 3 | The 750-800 | 3 | - | |

| 950 | 3 | There is no | There is no | C | |

| 950 | A third | There is no | There is no | - | |

| Water spray combustion test | 650 | 1/2 | There is no | There is no | W |

| Mechanical shock vibration combustion test | 650 | A quarter | There is no | There is no | - |

| 750 | A quarter | There is no | There is no | - | |

| 950 | A quarter | There is no | There is no | Z | |