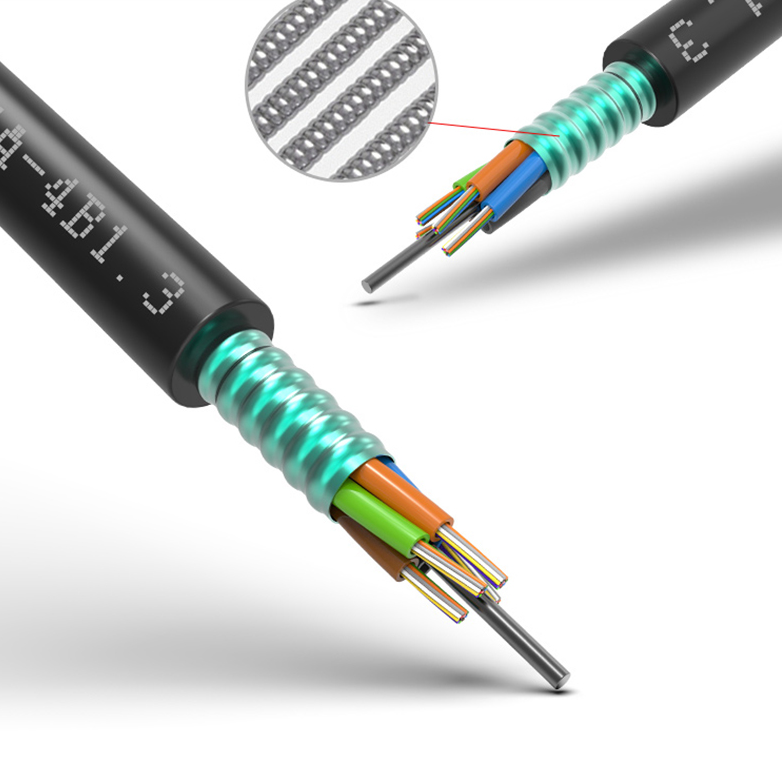

Chemical special optical cable GYTZA33 manufacturers

- Tel:0550-7591188

- Fax:0550-7591188

- Email:2136705934@qq.com

Description

Technical data:

1.1 For direct burial

1.2 All optical cables are directly buried, multi-mode fiber is 62.5/125µM, single-mode fiber is 9..10/125µM, high modulus loose tube is used, and the inner filling is round.

1.3 Use phosphating steel wire as reinforcement.

1.4 The core loose tube is twisted around the strength member and has a cladding.

1.5 The sheath is made of materials that can resist chemical action, and the inner sheath is a composite type of aluminum and high-density polyethylene.

1.6 Directly buried optical cable is steel wire armored, low halogen, flame retardant polyethylene outer sheath.

2.1 Fiber geometry

Fiber cladding smuggling: 125±2µM

Concentricity Error: <1.5µ M

Cladding out-of-roundness: <2%

2.2 The primary J sheath of the optical fiber is UV-cured propionate resin.

3.1 High-modulus plastic is used for the secondary overmolding.

3.2 The diameter of the casing is: 2.0±0.5MM

3.3 The sleeve is filled with optical fiber ointment.

The 4 cable cores are filled with fiber optic grease.

5.1 Optical fibers are distinguished by six colors: blue, orange, green, brown, gray and white.

5.2 The casing is also distinguished by six colors: blue, orange, green, brown, gray and white.

6.1 The optical cable is filled with longitudinal water blocking tape and water blocking cable paste.

6.2 Filling material shall not interfere with other materials.

6.3 There is no foreign matter such as dust and iron filings in the filling material.

6.4 Filler temperature range:

Temperature point: not lower than 70 ℃ (ISO2176 experimental method)

Drunk height: no more than +175℃

7 Cable core plus non-hygroscopic longitudinal wrapping tape, the overlap rate should be at least 3MM

8 The optical cable shall have a longitudinal cladding of aluminum tape with a laying probability of at least 3MM, a thickness of 0.15±0.025MM, and a double-sided coating protective layer with a thickness of at least 0.3MM. The aluminum tape shall have electrical continuity properties.

9. A layer of high-density polyethylene sheath is extruded outside the aluminum strip, with a nominal thickness of 1.0MM, a minimum thickness of not less than 0.8MM, and the cable core is round and free of impurities.

10. Squeeze a layer of polyacrylamide to protect the magnetic field on the high-density polyethylene sheath, the nominal thickness is 0.5MM, the minimum thickness is not less than 0.3MM, the cable core is round and free of impurities.

11 Galvanized steel wire armor, tensile strength is 300-550N/MM2, steel wire diameter: 1.0MM

12 The outer sheath is low halogen, black flame retardant polyolefin material.